. . |

|

|

|

|

As the North American representative for Arcotronics Technologies Srl of Bologna, Italy, we are pleased to support their expertise in designing and building winding and assembly equipment for metallized film, film/foil and aluminum electrolytic capacitors. Through their superior quality and craftsmanship, they have earned a worldwide reputation for supplying the finest winding equipment available to the capacitor industry. Below is an abbreviated listing of some of the types of equipment Arcotronics currently has available for film and electrolytic capacitors: |

Arcotronics Technologies S.r.L. has designed a complete range of medium and high speed taping machines for formed tape packaging and reel and ammo packing of leaded components. These machines are capable of not only feeding and taping the components but also testing, orienting, lead trimming and similar operations. All machines can be custom modified to meet your exact requirements. Winter-Wolff offers taping machines for any application, including:

The Embossed Tape Forming Machines built by Arcotronics are designed for high volume production with very reliable and accurate pocket production. The output of the finished tapes can go onto a reel or directly feed a customer's taping machine. Our current range of machines produce tapes from 8 to 44 mm wide. Design is currently underway for widths through 56 mm. Arcotronics can custom manufacture a wide variety of pocket designs to the strict tolerances needed for the packaging of surface mount components. As North American representative for Arcotronics' taping products, Winter-Wolff welcomes your inquiries regarding standard or custom machines.

|

2A S.r.l., part of Arcotronics Technologies S.r.L., is an automation specialist for assembly and processing of small to medium sized components. 2A has developed a strength in the film and electrolytic capacitor fields with a full range of machinery for manufacturing and testing of these products. Their automation expertise has led them to build machinery for the medical, audio, munitions and many other industries. Their capacitor machinery lines include but are not limited to: |

Most of the 2A machines built are custom designed or tailored to each individual manufacturers' requirements and built in a modular fashion. This enables manufacturers to purchase an entire line either all at once or piece by piece. As the local representative for 2A, Winter-Wolff welcomes your inquiries for standard or custom designed machines to meet your specific assembly or manufacturing requirements.

Using their vast experience with the assembly and handling of small components 2A has designed and built machines specifically for the assembly of sensors and photocells. These machines deliver the consistent quality, flexible production and low cost that only the best automation can provide.

All of these machines incorporate sophisticated test systems throughout the assembly process. This ensures all the parts produced on the production lines are of the highest and most consistent quality. We use mechanical, electrical and vision systems as part of our in-line quality systems.

While each machine is designed and tailored to each customerís unique requirements we have prepared catalogue sheets outlining the functions of a typical machine:

2A257 Sensor

Assembly Line (PDF

Format)![]()

2A261

Long Leaded Photocell Resin Filling, Curing and Testing

Line (PDF

Format)![]()

We would be pleased to review your specific assembly requirements in depth and together work to develop equipment suitable for your specific needs.

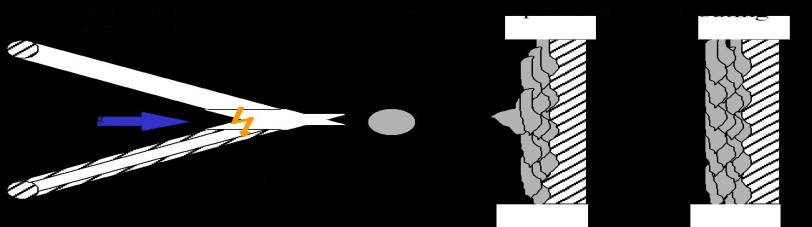

OSU of Duisburg, Germany was the first

company to commercialize metal arc spray equipment. Today

they have used their expertise and technology to develop a

special line of metal spray equipment for use in the

capacitor industry. The CAP Series Thermal Spray lines

were built after an extensive testing and development

program with capacitor manufacturers. The systems

incorporate the special needs of film capacitor producers.

The OSU CAP systems provide capacitor manufacturers with

uniform spray thickness, controllable particle sizes and

most importantly the lowest possible melting voltages in

order to prevent capacitor section damage due to excessive

heat during the spraying process.

The OSU CAP Series Arc Spray Equipment can endspray a wide

range of base metals and alloys onto the end of film

capacitors. All the metals can be sprayed at relatively

short spray distances. The shortened spray distances

minimize metal waste and increase consistency of the

endspray layer. The key to achieving these performances

lies in the special design of the power supply and the

spray gun nozzle. The OSU CAP Series power supplies are

built exclusively for OSUís metal arc spraying process.

As part of OSU design philosophy the CAP Series systems

are simple to run and highly reliable. All their systems

have few consumable spare parts in order to keep running

times maximized and operating costs minimized. Detailed

data sheets for these units are available below.

OSU Capacitor Arc Spray

System CAP 150 (PDF

Format)![]()

OSU Capacitor Arc Spray System CAP

300 (PDF

Format)![]()

|

||||||||